OPTIPOW AIR DUST COLLECTOR INSTALLATION

ASSEMBLY INSTRUCTION

Before the assembly of the OPTIPOW units, an accurate cleaning of the internal of the pressure tank is of great importance. Any particle in the tank could in the future give serious problems regarding the operation of the pulse valves.

pulse valve for dust collector

The OPTIPOW valve is as standard made for vertical installation. When the valve shall operate horizontally an extra internal spring has to be used. By that the plunger will always be in closed position when pressurising the cleaning system.The OPTIPOW is normally delivered as one unit in a special package. For detailed instructions regarding erection of separate parts, see OPTIPOW assembly drawing.

Unpack the valves at first when mounting them.

Check that there are no visible damages on the valve.

Check that there are no foreign materials inside of the valve.

Check that the top of the pulse pipe is smooth without any burrs.

Position numbers below refers those mentioned in figure 1.

Put the plunger (pos 4) on the top of the pulse pipe. Lubricate the O-ring on the outer side of the valve house (pos 1) and match the house to the plunger. When installing the pulse valve be careful not to damage the O-ring. Tum the house so that the solenoid is pointing in right direction. Screw the four bolts with fingers as long as possible and make then the last setting with tool cross-wise to avoid damages to the O-ring. Torque according to specifications.

Optipow Solenoid Valve

The service life can reach 1,000,000 times. Low temperature resistance -60 ° C and high temperature 150 ° C. Widely used in thermal power plant air purification and dust removal, glass factory dust removal, laboratory dust removal, and other industrial dust removal. We have a sales system and after-sales service system all over the world. Our goal is to continuously improve quality and continuously reduce costs, till customer satisfaction.

Low loss of compressed air: the OPTIPOW pulse valve reduces the amount of compressed air consumption compared to diaphragm type.

Compact size: OPTIPOW pulse is much smaller than the diaphragm valve shape the pulse valve shape, which means that the bag spacing not is restricted by the size of valve, only the process parameters (gas Bubbe, without filter, fly ash type and concentration) determines the bag size, two OPTIPOW pulse valve short distance you can go to 160mm.

OPTIPOW pulse valve has two specification 105 and 135, the number represents the diameter of the piston.

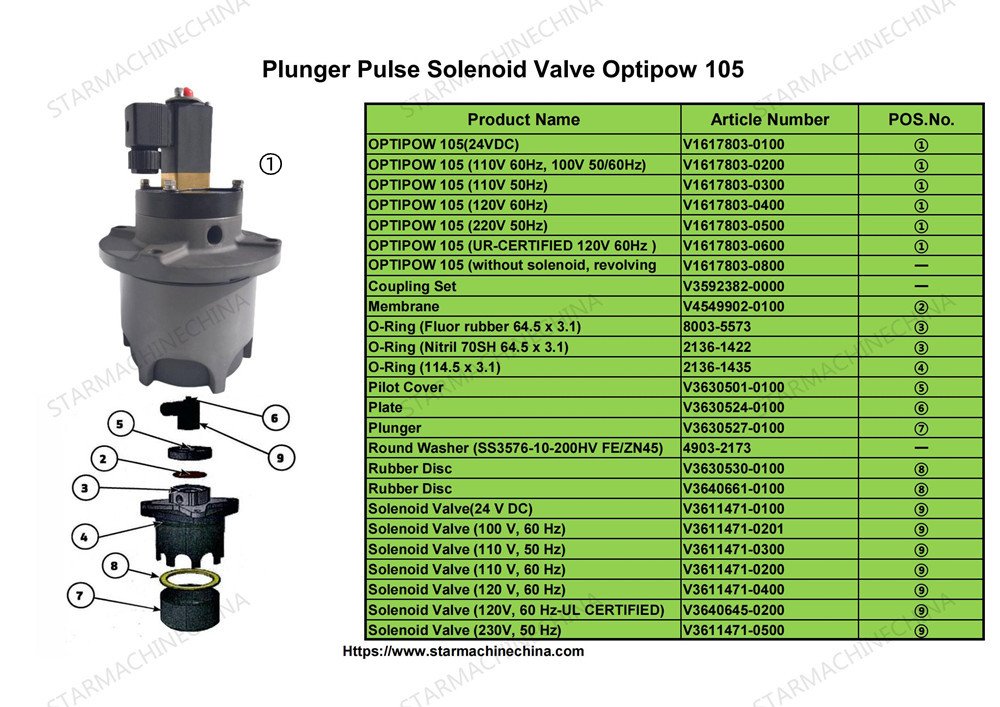

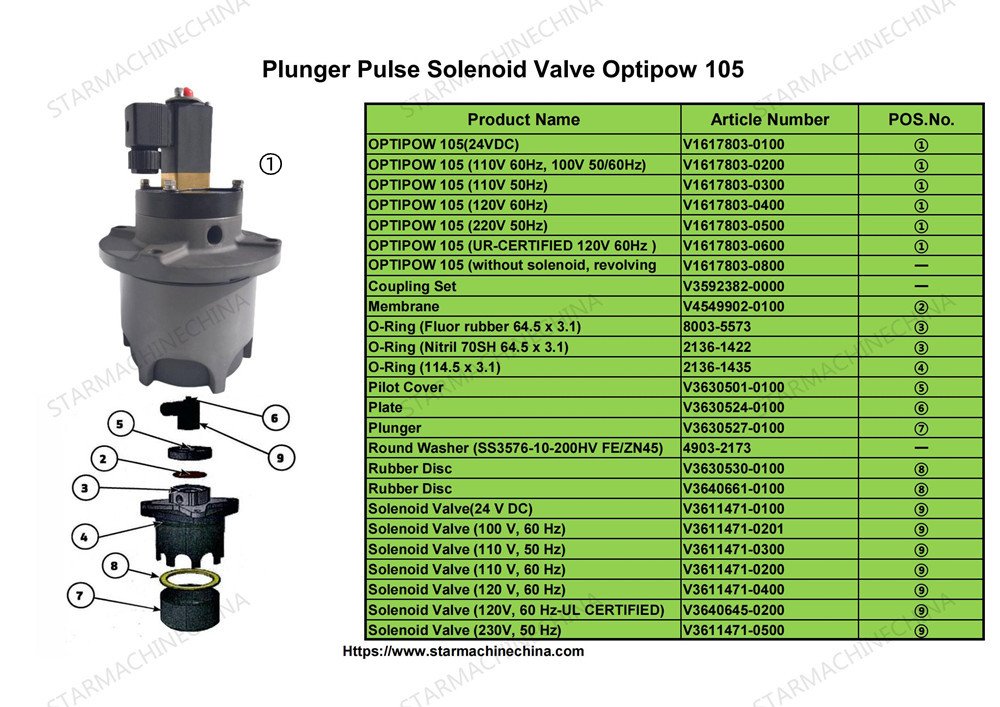

Optipow piston type pulse valve OPTIPOW105

Piston diameter 105mm

The number of filter bags: 30

Length of filter bag: 10M

Piston type pulse valve V1585320

Piston type pulse valve V3630501

OPTIPOW 105 (24 VDC ) V1617803-0100

OPTIPOW 105 (110V 60 Hz, 100V 50/60Hz) V1617803-0200

OPTIPOW 105 (110V, 50 Hz) V1617803-0300

OPTIPOW 105 (110V 50Hz, 120V 60Hz) V1617803-0400

OPTIPOW 105 (220V, 50 Hz) V1617803-0500

OPTIPOW 105 (UR-CERTIFIED 120V,60HZ) V1617803-0600

OPTIPOW 105 (without solenoid, revolving 90° C) V1617803-0800

Coupling set V3592382-0000

Membrane V4549902-0100

O-Ring (Fluor rubber 64,5 x 3) 8003-5573

O-Ring (Nitril 70SH 64,5 x 3) 2136-1422

O-Ring (114,5 x 3) 2136-1435

Pilot cover V3630501-0100

Plate V3630524-0100

Plunger V3630527-0100

Round washer (SS3576-10-200HV FE/ZN45 Erection details) 4903-2173

Rubber disc V3630530-0100

Rubber disc V3640661-0100

Screw (ISO4762-M10x30-8.8

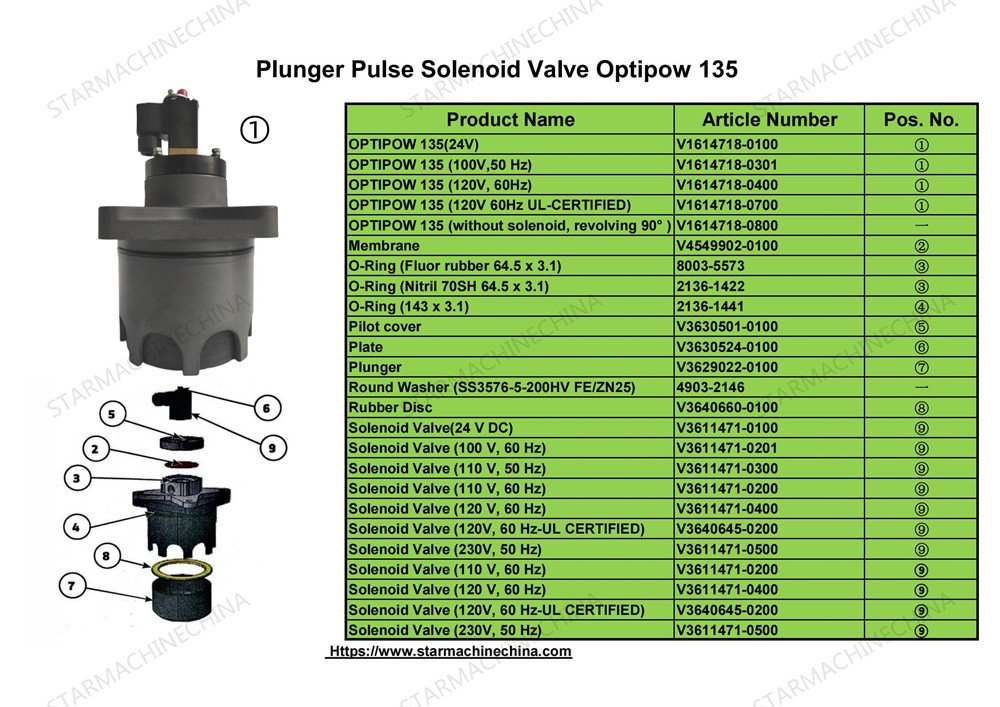

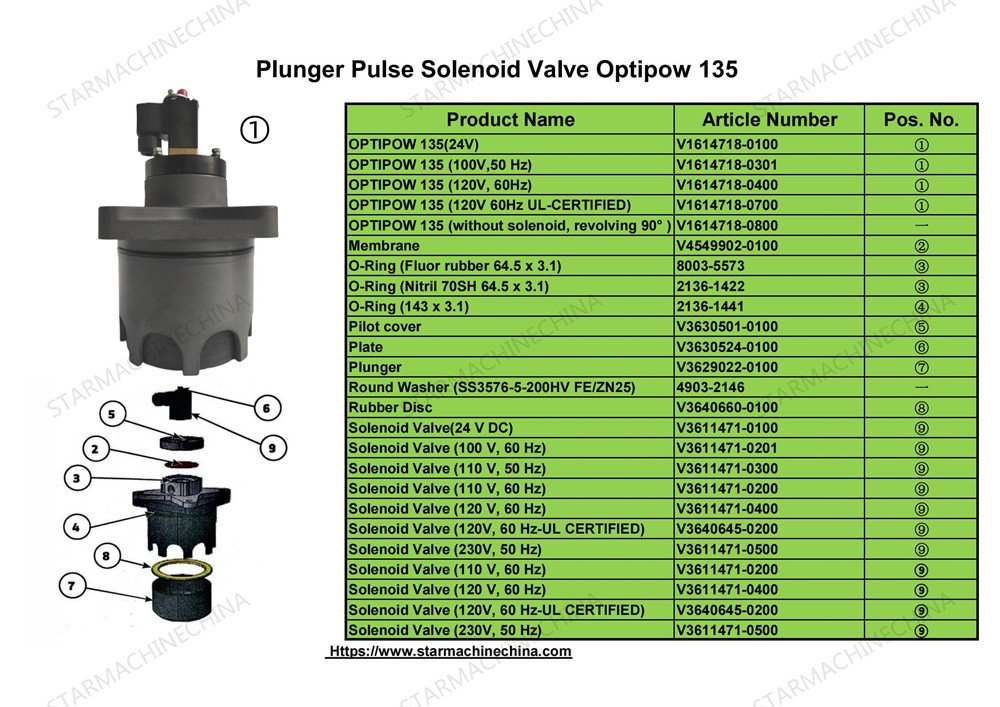

Optipow piston type pulse valve OPTIPOW135

models of OPTIPOW piston pulse cleaning valve

OPTIPOW 135 (24V) V1614718-0100

OPTIPOW 135 (100V, 50 Hz) V1614718-0301

OPTIPOW 135 (120V 60Hz) V1614718-0400

OPTIPOW 135 (120V 60Hz UL-CERTIFIED) V1614718-0700

OPTIPOW 135 (without solenoid, revolving 90° C) V1614718-0800

Membrane V4549902-0100

O-Ring (Fluor rubber 64,5 x 3) 8003-5573

O-Ring (Nitril 70SH 64,5 x 3) 2136-1422

O-Ring (114,5x3) 2136-1441

Pilot cover V3630501-0100

Plate V3630524-0100

Plunger V3629022-0100

Round washer (SS3576-5-200HV FE/ZN25) 4903-2146

Rubber disc V3640660-0100

Solenoid valve (24 V DC ) V3611471-0100

Solenoid valve (100 V, 60 Hz) V3611471-0201

Solenoid valve (110 V, 50 Hz) V3611471-0300

Solenoid valve (110 V, 60 Hz) V3611471-0200

Solenoid valve (120 V, 60 Hz) V3611471-0400

Solenoid valve (120 V, 60 Hz-UL CERTIFIE ALSTOM's new OPTIPOW compact piston pulse cleaning valve ALSTOM's OPTIPOW new compact piston pulse cleaning valve is mainly used for bag cleaning and installation on a round drum.

Advanced Optipow Valve Parts Processing Workshop

WHY CHOOSE US

1. Reliable Quality Assurance System;

2. Cutting-Edge Computer-Controlled CNC Machines;

3. Bespoke Solutions from Highly Experienced Specialists;

4. Customization and OEM Available for Specific Application;

5. Extensive Inventory of Spare Parts and Accessories;

6. Well-Developed Worldwide Marketing Network;

7. Efficient After-Sale Service System

International Express, Air, Sea and other Delivery Methods Can Be Selected to Delivery